Not A Packaging Engineer, Just Play One On TV

Back-To-School has a very short selling season targeted to a very finite audience, each year relatively based on the number of children meeting the specific demographics for specific products. It is also fiercely competitive.

Supplying the product is only half the battle. Presentation is very critical and how an account presented a particular product the previous year may have no bearing on this year’s plans. Displays are important for not only attracting customers but also for easy setup of large quantities of cumbersome products as well as how shoppable it is for a store’s customers.

Prior to my involvement, the pallet program consisted of a half pallet, made up of 324 boxes on a 24″ by 40″ pallet, and a full pallet, made up of 576 boxes on a 48″ by 40″ pallet. Each version had separate corrugate components for constructing the pallets. Due to the layout, the full pallet maxed out at 576 boxes, not even truly a “full” pallet. This was costly for obvious reasons… two sets of cutting dies and printing plates… and for less obvious reasons… lower production runs or potential excessive inventory of corrugate components and less manufacturing flexibility.

A handful of corrugate suppliers and packaging engineers had tried numerous solutions to remedy the problem without success. Lower costs, increased flexibility, reduce components, increased product count… designed by a Marketing guy, relatively unchanged since 1998.

One Pallet Design to Rule Them All

The Magic Divider

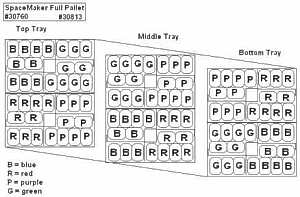

Seeing the need for improvement, and being new to the program and totally out of my area of expertise, I didn’t know better to leave well enough alone. Laying out boxes in the footprint of a pallet…a rather unscientific approach…a new layout was developed around this new divider. Rather than several components, this divider was made up of one component used twice to form the tray support and product divider, to be used on both the pallet and half pallet.

Lower Cost

Now, the only components that were specific to the two versions, were the pallet skirts, a large HSC to cover the half pallet, and for the full pallet, a large J-shroud (using two) for the sides and a second pallet skirt used as a cap… the least expensive of all the corrugate components.

Increased Flexibility

Two half trays were used side-by-side for the full pallet. With similar components, larger production runs could be made and larger quantities could be purchased from the corrugate suppliers, lowering overall costs. This flexibility also allowed Eldon to bulk build product and delay building the pallets until later, hoping that most BTS buyers had finalized the quantity of full pallets versus half pallets.

Easier Assembly

To top it off, this design was easier to pack out. Especially since the line workers only had to know one setup for the corrugate… typically the hardest and most time-consuming part of the process. With fewer components, less space was needed at the construction area and less concern for stopping production because of missing components. Where pallet was built before, now two pallets and a half pallet could all be constructed simultaneously.

To round it all out, I created an assembly schematic layout for the production floor and a special “BTS Pallet” label with an apple icon to draw more attention at store receiving.

PDQ Displays Make Move To Everyday

PDQs allow the stores to stock shelves quickly, especially during the busy Back-To-School season. Shipped with an HSC cover, the store personnel simply cut the tape holding the HSC to the display, slide the HSC off, and then slide the PDQ display onto the shelf.

Rather than developing blank corrugate displays, Eldon utilized the PDQs as additional billboard space to call attention to the products. Likewise, the sides could have been left blank or used as even larger billboards, but openings were cut in the sides to help bring visibility to the product when placed on an endcap and to also help light to enter the displays to help highlight and illuminate the product.

Nearly every box required its own PDQ due to dimensional differences. For boxes like the Pencil Pocket™, the PDQ not only had to hold the product, but the front opening had to keep the product from falling out without hindering the actual removal of the product when placed between shelves.

While the regular boxes could be neatly stacked on top of each other, the licensed product created even greater challenges. After all, if you can’t see the label, then the product looks like any other box. Wrap under labels with the licensor’s logos helped to call attention to the product if it was stacked, and the other half of the label contained the UPC, so only one label needed to be applied. By including a small corrugate pad in the PDQ, the product could be stood on end to display the label, and stacked on top of the pad to maximize the quantity of boxes and for best utilization of the shelf space at the stores.

Utilizing PDQs allowed the stores to greatly reduce the amount of time to set a planogram, as well as easing the upkeep. In the end, it became cost-justified to transition most of the everyday business into these displays.

PDQ Development

Early version allowed good visibility of product from front and sides, but didn’t provide enough side wall to hold boxes in if bumped. Final version provided a good compromise between securing the product and also allowing good visibility.

The same cutting die was able to be used for the Thingamabox™ Nintendo® version but with a different layout using corrugate slip to allow lower boxes to stand up-right to show labels.